What’s your best path forward when it comes to pallet strategy? Many companies ship pallets one way, including the pallet into the cost of goods. Once emptied, the pallet becomes the property of the customer. Other companies utilize reusable pallet programs – sometimes called closed-loop systems, where they retrieve empty pallets from customers and then use them again. Additionally, some pallet users lean on pallet rental providers, particularly for 48×40” applications in fast-moving consumer goods. A lot of companies use a combination of such approaches. This article will examine the growing buzz around reusable packaging and how that can translate for your pallet program. Is pallet reuse in a closed-loop system right for you?

To be clear, interest in reusable packaging has been trending upward in recent years. Studies have identified it as a potentially powerful way to reduce packaging costs and environmental footprint, most recently in consumer applications such as food service. For example, a 2023 study from the Ellen MacArthur Foundation determined that reusable packaging can reduce carbon footprint by 35% to 70% compared to single-use plastic packaging. The same principle holds for pallets.

How a Reusable Pallet Program Can Cost Less and Lessen Footprint

Just as in the case of reusable packaging mentioned above, pallet reuse programs have the potential to reduce greenhouse gas impact and cost significantly. It works like this.

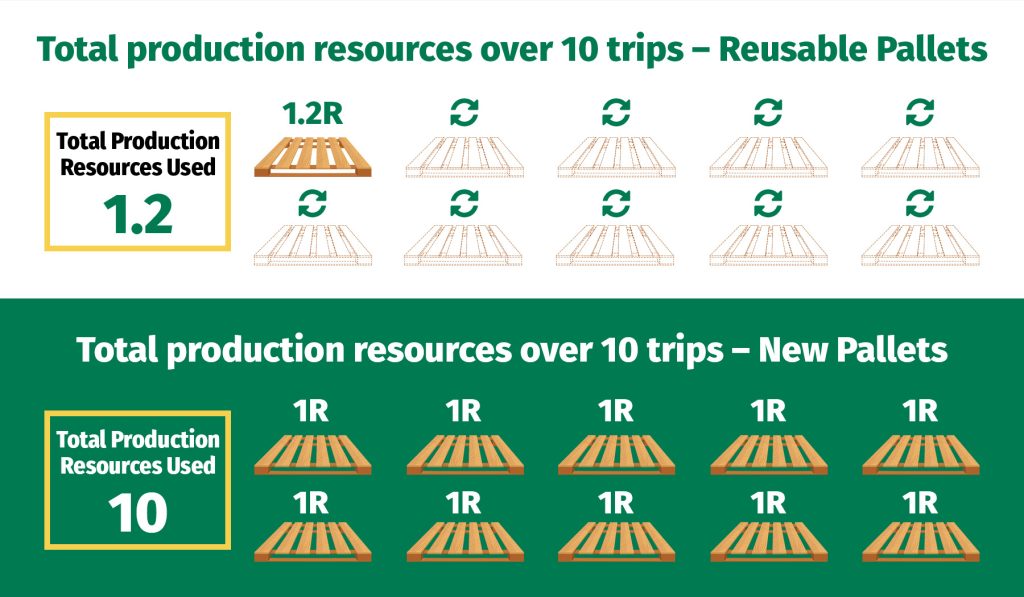

Simply put, each time a limited-use pallet (Pallet A) is manufactured, it consumes materials, labor, and energy. The consumption of these inputs has implications for sustainability and cost. But let’s say you build a more durable pallet (Pallet B) that takes 20% more resources to construct, for example, but instead of using it once, you use it ten times before repair. Being used ten times versus a single time, the difference is staggering – an 88% decrease in resources consumed on a per-trip basis, as shown below. This does not even consider the amount of trips after repair, which would further strengthen the business case for a reusable pallet system.

Result: Material and energy impact of only 12% of a single-use pallet per trip, based on ten trips.

For many applications, the added impact of reverse logistics is considerably less than the sustainability impact and cost of manufacturing another new pallet for each trip. In such environments, the case for pallet reuse can be compelling. However, there are cases where reuse isn’t the obvious way forward. We will touch on that further below.

There are other potential benefits of a pallet reuse program. For example, a more robust pallet designed with repeated use in mind might perform better in the supply chain. While investing in a premium pallet for a single use might not make sense, the cost is easier to justify when prorated over several pallet trips. The customer receiving the pallet also enjoys a better quality pallet.

An additional benefit of pallet reuse programs is that because empty pallets are returned to the shipper, the receiver does not need to be concerned with disposing of the empty pallets.

When a Pallet Reuse Program Might Not Make Sense

Pallet reuse programs work best when there are regular deliveries of sufficient volume and a reasonable backhaul distance. Some popular applications for reusable pallets include beverage, grocery, tier suppliers shipping to assembly plants, construction materials, and more. Applications such as daily milk or bread deliveries are commonly associated with reusable packaging and pallet systems.

Returnable or closed loop pallet programs can be more challenging to establish where shipping distances are greater and/or volumes shipped are smaller. If pallet return is too expensive or too many pallets go missing, the advantages of a reuse program can be quickly lost. Creative partners, however, can sometimes find ways to return smaller quantities of empty pallets economically while limiting losses.

Aside from the logistics of distance and adequate volumes, a crucial element of successful reusable pallet programs is stakeholder participation throughout the supply chain. Customers’ cooperation in accumulating and safeguarding empties, as well as transport providers’ retrieval and return of empties, is crucial. Stakeholder cooperation is easier when it is understood that the reusable pallet program is a mutual win-win, both economically and environmentally, for all parties involved.

Reuse is trending in supply chain packaging, and many companies are taking a closer look. If you want to evaluate whether a reusable pallet or closed-loop program is right for your company and your supply chain, contact PalletOne. We are here to help.