As 2023 ended, several shipping companies were looking to reroute cargo vessels in the wake of attacks in the Red Sea, resulting in rising costs and significant delays. Prospects for the first quarter of 2024 remain uncertain as diplomatic efforts continue. Such global escalation of tensions might further drive the already buoyant nearshoring trend, with several reports of rapid manufacturing growth in Mexico and other Latin American countries. This trend has significant implications for supply chain planning, including unit load design and pallet redesign.

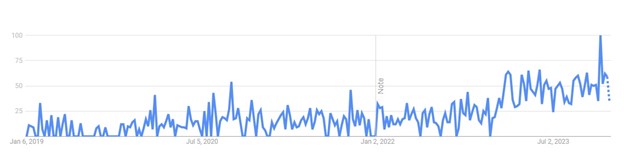

A quick look at Google shows a dramatic spike in online searches for the term “nearshoring,” which could foreshadow further acceleration of the trend.

As discussed in our previous related article, nearshoring refers to relocating manufacturing and sourcing operations closer to a company’s primary markets, often within the same region or country, to reduce supply chain risks and enhance operational efficiency. It is similar to homeshoring, another approach to eliminating problems associated with offshoring.

A similar option includes homeshoring. Homeshoring, also known as onshoring, is the practice of locating business operations or customer service centers within the same country or region as the company’s headquarters, often as an alternative to offshoring, to benefit from local expertise, reduce language and cultural barriers, and enhance customer service quality. While it limits exposure to geopolitical risks, companies must still weigh the prospects of higher costs, more red tape, and extreme weather risks.

Businesses are increasingly embracing nearshoring in response to a rapidly changing global landscape marked by geopolitical risks and disruptions. Here’s an overview of the factors driving nearshoring, considerations for adapting to this supply chain approach, and the anticipated benefits.

Offshoring

-

Outsourcing to distant countries

-

Cost-effective but involves global supply chains. Supply chain disruption has resulted in increasing supply chain risk.

-

Asia Pacific, Europe and gobal

Nearshoring

-

Outsourcing to nearby nations such as Mexico

-

Cost-effective and allows for easy collaboration, but may require considerable investment and supply chain redesign, new challenges and benefits.

-

Mexico, Latin America

Onshoring

-

Sourcing from the home country

-

Often costly but avoids cultural differences and possible language barriers, can create a positive “Made in USA” brand image.

-

United States and Canada

Table based on Hatchworks.com with modifications.

The shift towards nearshoring is motivated by a set of compelling factors. These include:

- Reduced risk of international geopolitical disruption.

- Significantly shorter lead times and improved responsiveness because of closer proximity to the marketplace.

- Lower transportation costs resulting from goods traveling shorter distances.

- Requires less pipeline inventory because of the ability to replenish more quickly.

- Proximity to the head office, including similar time zones, can improve oversight and quality control.

- Cultural similarities offer the potential for more effective communication and management.

Nearshoring Challenges

While nearshoring offers numerous advantages, it also demands significant investment and strategic adjustments in supply chain operations, including pallet and unit load design considerations. As a starting point, new supply chain relationships require a comprehensive location analysis and potential supplier reviews. Other considerations include mastering local regulations, customs, and trade policies, integrating technology systems, and attention to labor availability.

However, one of the exciting possibilities for many nearshored supply chains is the opportunity for shippers to review their unit load design – optimizing the packaging, pallet, and load containment system within the constraints dictated by the handling environment.

With the elimination of floor loading into ocean containers and a shift to palletization at the manufacturing point, reducing stresses could offer the opportunity to decrease overall packaging costs. Likewise, new investments in material handling automation and shorter supply chains offer greater potential for pallet quality control and reuse programs. Each supply chain is unique and presents its own opportunities for cost reduction.

Many supply chains are moving closer to home. While building new relationships and transitioning logistics arrangements will be on the front burner for corporate leaders, such changes will also create opportunities at the unit load level. PalletOne’s unit load consulting service can help you make the most of it.