The block pallet has become increasingly visible in North American supply chains in recent decades. While it only accounts for around 20% of U.S. new pallet production, its market share has more than doubled since 2011. The versatility of the block pallet enabled by full four-way entry makes it highly prized in industries such as grocery, plastics/chemicals, and others.

For example, block pallets can provide substantial productivity gains in maneuvering unit loads on cramped loading dock conditions or expediting the quick unloading of trailers. But what goes into making a block pallet, and which version is best for you? In this installment, we look at the anatomy of the block pallet, including wood components and fasteners.

What goes into a block pallet?

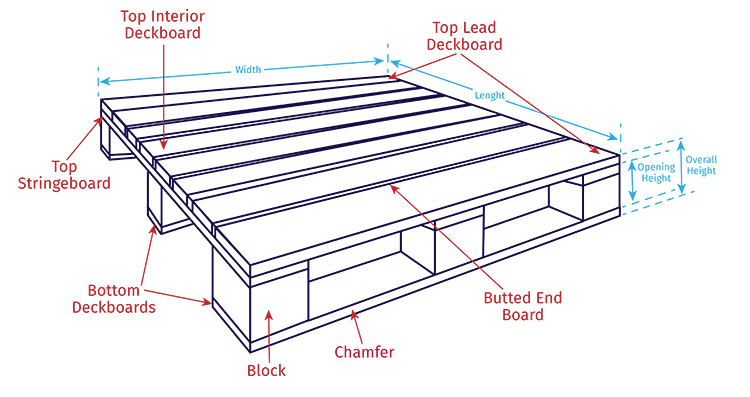

Let’s start at the top and work down. Wood deck boards typically comprise the top deck, although solid plywood or wood composite sheet material is sometimes used. Solid decks are valued in applications such as bagged goods that could settle between the deck board gaps and become damaged or for small items that might not be adequately supported with typical deck board spacing. Adding handholes in a solid top deck can facilitate easier manual handling.

Immediately under the top deck boards are the stringer boards. As seen in the image, the stringer boards are sandwiched between the top deck boards and the tops of the blocks, providing additional support and helping to distribute weight evenly. In a reversible block pallet (a pallet that can be used with either side up), there would also be stringer pallets sandwiched between the bottom of the blocks and the bottom deck boards.

Blocks are the defining feature of block pallets and the key differentiator as compared to stringer pallets. Positioned typically in a three-by-three grid, they anchor the top and bottom decks. Blocks can be cut from solid timber or formed from wood composite material. Some blocks are occasionally made by fastening multiple layers of solid wood boards or plywood together.

Composite blocks are popular for export pallets due to their uniform size and dryness, which aid in robotic placement and high-speed production. However, they are not universally favored due to concerns about the possibility of fiber shedding. This risk is addressed using different bonding agents and higher pressure during block formation.

Bottom deck boards are attached to the block bottom for non-reversible pallets. Typical pallet bottom configurations include the parallel base, picture frame (perimeter) base, and the cruciform base. The parallel base is shown in the diagram. In the parallel base, all bottom deck boards run in the same direction. Block pallets with a parallel base, such as europallets, can be nested together by flipping over every second pallet, interlocking them to increase transportation and storage efficiency.

Other bottom deck configurations include the perimeter base and the cruciform base. In perimeter base pallets, the bottom boards create a “picture frame” around the outside edge of the pallet, often with one or two center bottom components. The cruciform deck pallet is similar to the perimeter deck, with the addition of centerboards that are oriented in both directions. The advantages of these latter formats, particularly in the case of the cruciform base, are that they provide additional bottom deck coverage to distribute weight more evenly, and secondly, having bottom boards running in both directions enhances functionality with conveyors, regardless of the direction of travel.

Fasteners

Unlike stringer pallets, block pallets often use multiple nail sizes in the same pallet. For example, top deck board fasteners driven through the stringer board and into the blocks need to be longer, while nails fastening the top deck boards to the stringer boards (a combination referred to as the top mat) are shorter.

In a heavy-duty block pallet, a typical configuration might be 3” annular ring nails for top deck boards being driven through the stringer board into the block, 1 ⅝” smooth shank nails for the matt, and 2 ¼” annular ring nails to fasten the bottom deck to the blocks.

Final word

Simply put, those are the ingredients that go into a block pallet, but there is a lot more to it than that. Building block pallets is more complex than nailing stringer pallets, requiring specialized nailing equipment. At PalletOne, we have state-of-the-art block-nailing capacity and deep experience manufacturing them. If you are interested in switching to block pallets or stepping up to a better block pallet, we can help. Contact us today.